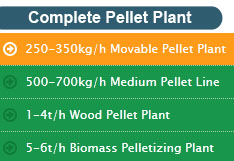

Complete Wood Pellet Mills

Pelletizing is the process of making the waste materials into solid fuel. The products are used for burning purposes. The wood pellet is one of the most commonly used pelletizing materials. The wood pellet can be made from any type of agro-forestry waste: Groundnut-shell, Sugarcane Biogases, Caster Shells/Stalk, Saw dust, Coffee Husk, Paddy Straw, Sunflower Stalk, Cotton Stalks, Tobacco waste, Mustard Stalk, Jute waste, Bamboo Dust, Tea waste, Wheat Straw,Palm husk, Soybeans husk, Coir Pitch Barks/Straws, Rice Husks, Forestry wastes, Wood Chips and many other Agro wastes. But the moisture content should be less than 12%,the grain size is below 5*5mm.

Complete Wood Pellet Mills Projects workshop:

Pelletizing is the process of making waste materials into solid fuel. The objects are used for burning purposes. Wood Pellet is one of the most commonly used pelletizing materials.

Flowchart of pellet mill line :

1. Raw material:

Pellet fuel is mainly made of sawdust, shavings and fines leftover after processing trees for lumber and other products. The raw material also can be corn or other biomass material.

2. Introduction of Process:

At a pellet mill, the material is dried, compressed and formed into small eraser-sized bits. They are clean, pleasant to smell and smooth to touch.Directly before pellet press, a product with a granular size of approx 4 mm and a residual moisture content of approx 15 % is required.

The technology can use PLC automatic control system. In the process of crushing and pelletizing, speed control system can be used for feeding material, which adjust the quantity of flow speed of material according to load of main motor. The moisture test points are designed for testing moisture of raw material and material after drying. The material with high or low moisture are separated and feed in back after processing.

Wood pellet Mill is the most important equipment, which have the following features:

(1).Crushing Process:

When the thickness of raw wood material is >10mm, and >50 * 50mm(L * W), we need use the wood chipper to chip them into small pieces, then crush the small pieces into wood powder which is less than 3mm in diameter by Hammer Mill (Crusher).

The best moisture content to pelletizing is about 13-15%. The GEMCO Rotary Dryer is made up of Stove and Main Rotary Dryer, which can reduce the moisture from 60% to 10%.

The stove is fueled by coal, which can largely save electricity consumption.The rotary dryer is specially designed for energy saving purpose, the surface of the dryer is covered with special cotton material sheet to prevent the heat from leaking.

(3). Pelletizing Process:

MZLH Wood Pellet Mill is the most important equipment, which has the following features:

2. Driving Gear adopts the high precision gear transmission structure. The wear bearing is SKF from Sweden. The ring die adopts the hoop fastening method.Comparing with the past bolt fastening method,this one is increasing the speed of discharge . As a result, the capacity is 10-15% higher than that of the belt transmission structure.

3. As per the ring die and roller of the wood pelleting mill, we have the excellent machining with the alloyed steel. And the heating treatment is also different from the other manufacturer in China.The carburizing treatment makes the depth of hard facing to 2mm, which improves the anti-abrasion of the ring die and roller more than 10 times. This can largely cut down the production cost.

(4). Cooling Process:

After the pelletizing process, the temperature of the wood pellet is about 60-80 degree Centigrade, and the moisture content of the wood pellet is about 15%.So we need use a cooler to reduce about 3-4% of the moisture, which makes the wood pellet easy to store.But according to the feedback from some foreign customers, their local climate is very humidity; they hope to cool the wood pellet with moisture 7-8%. In order to satisfy the different needs from different clients, we offer you with a new kind of stabilizer combined cooler.

(5).Packing Process:

After the cooling process, the wood pellet will not directly enter into the fuel process to avoid the affect from the damp. The packing process is necessary. In this process, we assemble the best domestic semi-auto packing machine to you.Generally, most customers need one small weight range scale with auto sealing packing machine, and one large weight range scale with semi-auto packing machine. For the small scale, the weight range will be 15-25kgs per bag.For the large scale, it will be 1000kgs per bag or 800kgs per bag.These will up to the different needs from the customers .

3. Tech. Data

- Capacity: 1 t/h ~ 6 t/h (based on a mixture of 50% pine and 50% spruce wood)

- Raw Materials: Wood sawdust, logs from soft wood

- Product Diameter: 6mm or 8mm (optional)

- Product Density: 1.1~1.3 kg/m3

- Final Moisture: <8%

Note: The above data concerning capacity, consumption may vary depending on the origin, nature of the raw material.

Current Data

- Service Voltage: 380V, 50Hz

- Control Voltage In Switch Cabinet: 220V, AC

- Signal Voltage For Valves, Initiators 24V, DC

- Painting Optional by users

4. Highlight of our equipments

- Reliable continuous operation

- Low energy consumption

- Low maintenance cost

![]() Note:For the complete wood pellet plant, the Dust Filtering is a heavy and important task. We assemble the Common Dust Collector(known as cyclon) and Impulse Dust Filter.Fo the exhausting air, we use Water Film Dust Collector to realize the free dust situation in the process of Drying and Cooling which generate plenty of dust in the working time.

Note:For the complete wood pellet plant, the Dust Filtering is a heavy and important task. We assemble the Common Dust Collector(known as cyclon) and Impulse Dust Filter.Fo the exhausting air, we use Water Film Dust Collector to realize the free dust situation in the process of Drying and Cooling which generate plenty of dust in the working time.

Complete Wood Pellet Mills

Small Mobile Pellet Plant

Biomass Pelletizing Plant

Drum Chipper

Wood & Straw Crusher

Hammermills

Heat Stove

Rotary Drum Dryers

Ring Die Pellet Mill

Pellet Mill With Ring Die

Flat Die Pellet Mill

Spare Parts Dies & Rollers

Steam Boiler

Cooler

Pellet Packing Machine

PLC Control for Pellet Mill

Conveyor

Pellet Pulse Dust Collector

Magnetic Separator

Pellet Stove Fireplace

Small Pellet Mill

Spanish

Spanish French

French Russian

Russian