Pellet Mill : Dryer

Pellet Mill: Drum Dryer Technical Parameters:

The rotary dryer is your best choice for high capacity applications involving high moisture, friable, free-flowing commodity products and by-products. A rotating drum and strategically positioned flights combine to lift and shower the product evenly through the air stream. Thermostatical controller discharges the temperatureof the air,assures the precise final moistures and great sensitivity to variegate the conditions of the product . Single-pass or three-pass configurations are available to match product characteristics. Heating options includeAfter the dank raw material is put into the dryer, it is turned over through the string-up rake which is inside of the cylinder and distributed uniform in the dryer, contacted fully with the countercurrent hot air. It accelerates the heat and mass conducting of dry. During the period of drying, the raw material is effected by the stirring-up rake with gradient and the hot air.It can be moved and passed through the dry region to start valve and discharge the final product.

Pellet Mill: Drum Dryer Technical Parameters:

| Model | Diameter (mm) | Length(m) | Power(kw) | revolution(r/min) |

| HZG6 | 600 | 4,5,6,7,8 | 3-5.5 | 3-20 adjustment |

| HZG8 | 800 | 4,5,6,7,8,9,10 | 5.5-7.5 | |

| HZG10 | 1000 | 6,7,8,9,10,11,12 | 5.5-7.5 | |

| HZG12 | 1200 | 6,8,10,12,14,16 | 7.5-11 | |

| HZG15 | 1500 | 8,10,12,14,16,18 | 11-15 | |

| HZG18 | 1800 | 8,10,12,14,16,18,20 | 15-18.5 | |

| HZG22 | 2200 | 10,12,14,16,18,20,22,25 | 18.5-22 | |

| HZG24 | 2400 | 12,14,16,18,20,22,25 | 22-30 |

|

Item(m) |

capacity(t/h) | revolution(r/min) | motor power(kw) | install angle(degree) | Temp.of final |

| f1.0×5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | =1.5% |

| f1.2×6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | =1.5% |

| f1.5×12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | =1.5% |

| f1.8×12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | =1.5% |

| f2.2×12-22 | 7-12 | 0.6-6 | 22 | 3-5 | =1.5% |

| f2.4×15-20 | 9-15 | 0.6-6 | 30 | 3-5 | =1.5% |

| f3.0×25 | 16 | 0.6-6 | 55 | 3-5 | =1.5% |

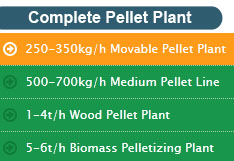

Product List

Complete Wood Pellet Mills

Small Mobile Pellet Plant

Biomass Pelletizing Plant

Drum Chipper

Wood & Straw Crusher

Hammermills

Heat Stove

Rotary Drum Dryers

Ring Die Pellet Mill

Pellet Mill With Ring Die

Flat Die Pellet Mill

Spare Parts Dies & Rollers

Steam Boiler

Cooler

Pellet Packing Machine

PLC Control for Pellet Mill

Conveyor

Pellet Pulse Dust Collector

Magnetic Separator

Pellet Stove Fireplace

Small Pellet Mill

Quality Guaranteed

Spanish

Spanish French

French Russian

Russian